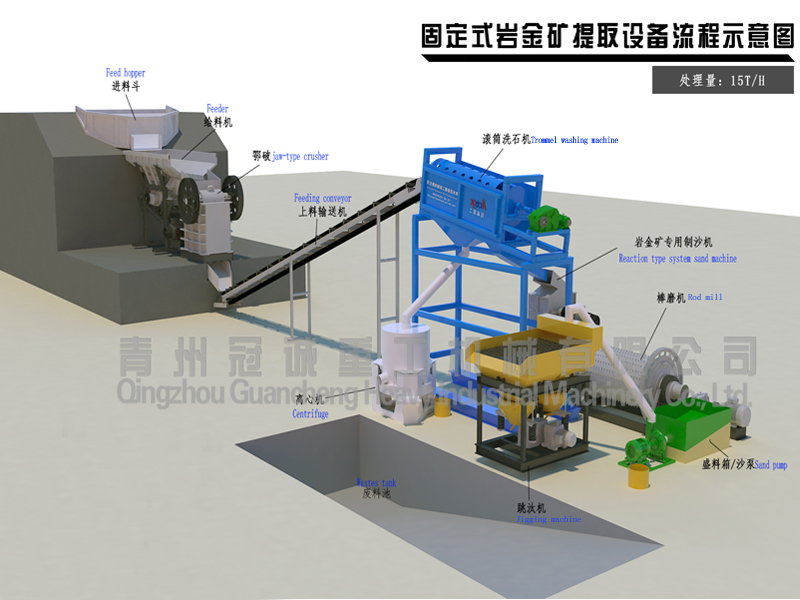

Crushing plant

Technological process

Raw material getting through Feed hopper,then moved into shaking feed machine and into jaw-type crusher to be crushed,the crushed material from conveyor moved to trommel screen to be separated into 2sizes≦6mm or≧6mm

The smaller size materila(≤6mm) flow into 80#centrifugal concentrator for further separation,the scap material washed to waste pool.The bigger size material(≧6mm)then go through specialized sandmaking machine of rock mineto be crushed into sands to be collected,the others material getting into Rod mill then gold separating by 80#centrifugal concentrator,the scap material getting rid to the waste pool.

Detail Parameter

|

|

|

|

|

|

|

Feed hopper |

3500mm*2980mm 10mm thick steel 12# U steel |

- |

1pcs |

|

|

Shaking Feeder |

3800*960mm |

15KW |

1set |

|

|

Jaw-type crusher |

250*400mm |

15KW |

1set |

|

|

Conveyor |

Belt width 600m,Pole length 16m |

7.5KW |

1set |

|

|

Trommel washing machine |

Ø1000mm,length 3000mm |

7.5KW |

1set |

Including holidng frames, Feed hopper etc |

|

Specialized sandmaking machine of rock mine |

800*800mm |

75KW |

1set |

|

|

Rod mill |

2100*3000mm |

180KW |

1set |

|

|

Jigging machine |

JT5-2 |

7.5KW*2 |

2set |

|

|

Centrigue concentrator |

80#handling discharge type |

11KW |

1set |

|

|

6S Shaking table |

3000*1620*1360mm |

2.2KW*4 |

4set |

|

|

Sand pump |

4inch |

30KW |

1set |

|

|

Water pump |

|

7.5KW |

1set |

|

|

Water pump |

|

3KW |

1set |

|

|

Centrifugal pump |

|

5.5KW |

1set |

|

|

Pipe of centrifugal pump |

|

- |

30m |

|

|

Pipe of water pump |

|

- |

3pcs |

|

|

Feeding pipe of centrifuge |

Wire braided hose |

- |

10m |

|

|

Distributer Cabint |

|

- |

1set |

|

|

Generation unit |

200KW |

- |

1set |

|

|

Generate unit |

300KW |

- |

1set |

|

Previous content:Crushing plant

产品分类

/PRODUCTS- Gold Mining Machine

- Crusher equipment

- Dredger

- Sand Processing Machinery

- SOLUTION

- Gravity Beneficiation

联系我们

/CONTACTQingzhou Guancheng Heavy Industrial Machinery Co.,Ltd.

+86 536 3593111

地址:Dongjiande Village, Huanglou Street Office, Qingzhou, Shandong, China (Mainland)

电话:+86 536 3593111

传真:+86 536 3593111

手机:+86 15653473333,15053659999

Email:1592999333@qq.com