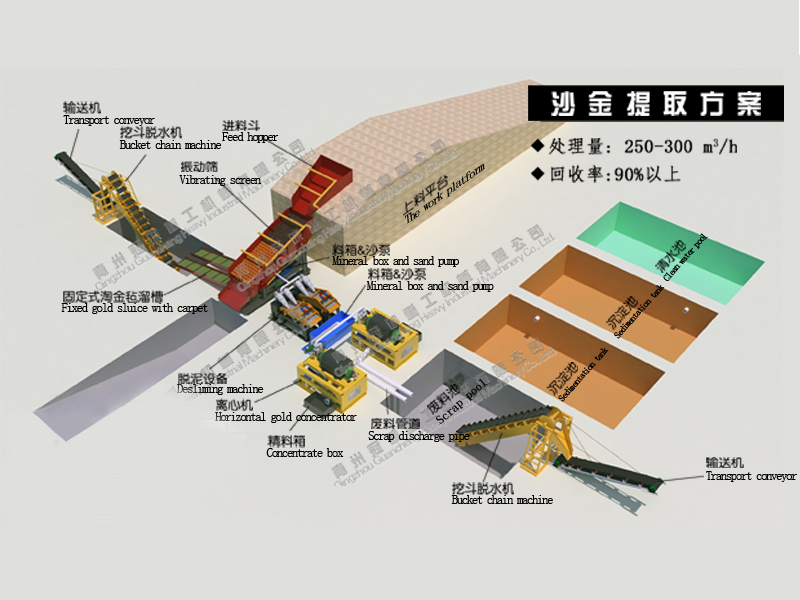

High recovery capacity 250-300m3/h alluvial gold separating machinery

Gold Mining Machinery technical process

The raw material getting into feed hopper then into vibrating screen by swilling of high pressure water to be classified into 3size,the big size,the normal price, the small size,the one in big size useless is directly to get rid to scrap pool.

The one in normal size to be recovered by 2fixed gold sluice with carpet,the scrap material to be transported by conveyor after the bucket chain machine taking water off.

The one in small size get into desliming machine by pumping of 1set 8inch sand pump (it’s efficiently the recover of gold concentrator by preventing surface gold covered by the muddy mineral),then the clay-off mineral getting into 2set of horizontal gold concentrator to get concentrate into mineral box,the scrap into scrap pool which finally transported to destination by conveyor after the process of taking water off by buck chain machine.

Gold Mining Machinery detail parameter

|

Production Name |

Specification |

Quantity |

Power |

Remark |

|

Feed hopper |

4000*5000mm |

1pcs |

- |

|

|

|

2100*6000mm

the other 3m with polyurethane screen mesh, |

1set |

18.5 |

Including base plate,holding frames etc |

|

|

1500*3500mm 0.55KW |

2set |

1.1 |

|

|

|

21.5KW |

2set |

43 |

|

|

|

1000*6000mm |

2set |

- |

With gold carpet |

|

|

60# 11KW |

2set |

22 |

|

|

|

|

1pcs |

22 |

|

|

|

|

1pcs |

15 |

|

|

|

|

2pcs |

6 |

|

|

|

11KW |

1set |

11 |

|

|

|

5.5KW |

2set |

15 |

|

|

|

|

1pcs |

- |

|

|

|

153.6KW |

|||

Previous content:Capacity200-300tph alluvial gold separting plant

产品分类

/PRODUCTS- Gold Mining Machine

- Crusher equipment

- Dredger

- Sand Processing Machinery

- SOLUTION

- Gravity Beneficiation

联系我们

/CONTACTQingzhou Guancheng Heavy Industrial Machinery Co.,Ltd.

+86 536 3593111

地址:Dongjiande Village, Huanglou Street Office, Qingzhou, Shandong, China (Mainland)

电话:+86 536 3593111

传真:+86 536 3593111

手机:+86 15653473333,15053659999

Email:1592999333@qq.com