Some Tips to the Application of the Lubrication of Impact Crusher

The impact crusher is a kind of mining machinery specially used to crush ore, which can crush a variety of ores, such as limestone, dolomite, calcite, and so on. It can be said that it is a very important ore crushing equipment in the gravel production line.

You are reminded by Guancheng Heavy Machinery, a professional mining machinery manufacturer, that in the ore crushing process the lubrication process is very important for the large-scale mining machinery like the impact crusher.

The operators should remember that during the long-time use process of the impact crusher the worn surface of the impact crusher should be lubricated immediately. However, the lubricants used are different due to different places and climates. Besides, if the machine has run for 8 hours, the lubricant should be injected into the bearings once. The bearings at both ends of the main shaft are lubricated with molybdenum disulfide grease.

For the user, it should be focused on that as for the impact crusher the lubricant should be replaced once every three months. Before the change of the lubricant, the bearings should be cleaned seriously with clean gasoline or kerosene. It would be better if the amount of the lubricant just injected into the bearings is 50%-70% of the volume of the bearing hollow cavity in control.

产品分类

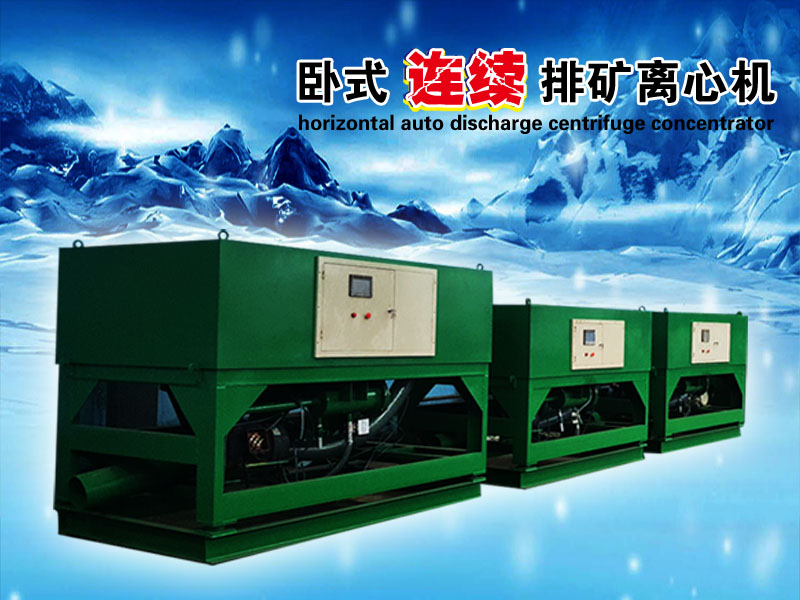

/PRODUCTS- Gold Mining Machine

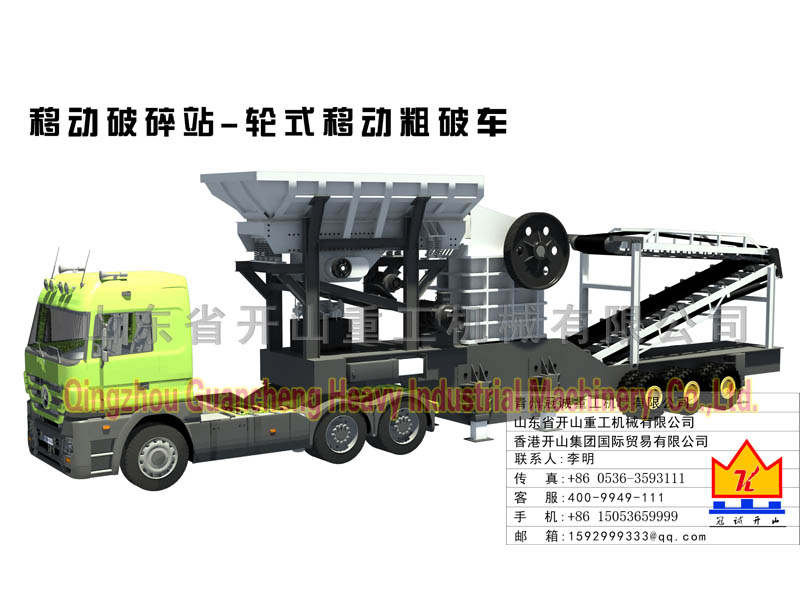

- Crusher equipment

- Dredger

- Sand Processing Machinery

- SOLUTION

- Gravity Beneficiation

推荐产品

/PRODUCTS推荐文章

/NEWS- Facts About Environmental Equipment

- To Focus on the Wearing Parts of Roller Crusher

- Some Tips to the Application of the Lubrication of Impact Crusher

- The Development of VSI Crusher Solves the Shortage of the Artificial Sand

联系我们

/CONTACTQingzhou Guancheng Heavy Industrial Machinery Co.,Ltd.

+86 536 3593111

地址:Dongjiande Village, Huanglou Street Office, Qingzhou, Shandong, China (Mainland)

电话:+86 536 3593111

传真:+86 536 3593111

手机:+86 15653473333,15053659999

Email:1592999333@qq.com