Working princple and operation notes of knelson centrifuge concentrate

Gold mining machine knelson series centrifuge concentrator is more and more widly used in mining solutions as gold mining machinery,how it works and what's the correct operation especially to personal safety,let's get it now.

1.Personal safety precautions

1.1About electricity

Three phase power supply is used in the system, which may be dangerous to human body

It needs to be very careful on worktime.

A. regularly check whether the terminal is in good touch

B. If a damaged electrical component is found, the element should be isolated before repair or replacement

C. check the electrical box is sealed to prevent water

D. only allow qualified electrical technicians to carry out maintenance work

1.2 About gold mining machine

A. please do not put tools, screws and other electrical appliances placed on the pump, so as not to cause an electric shock hazard

B. make sure that all the pipes are adequately secured and supported. Check the valve after opening the system to ensure that all valves are normally closed

1.3 Start up&shutdown

Check the system before the start of the total power supply, water is normally open or not, shut down while all the system's power is off, water, other operations must comply with the open and shut down procedures to ensure the safety of the staff

1.4 Passageway

Adequate access and lighting shall be provided around the equipment for safe operation and maintenance

Ensure all operators are familiar with the safety issues related to the equipment

Be familiar with all pumps and valves,ensure smooth and adequate lighting around the facility

2.working principle and detail parameter

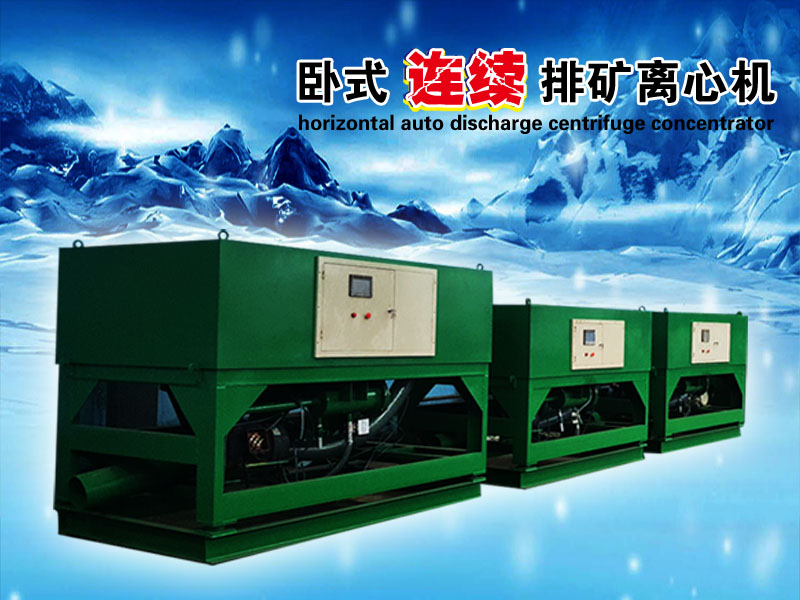

2.1knelson series centrifuge concentrator working principle

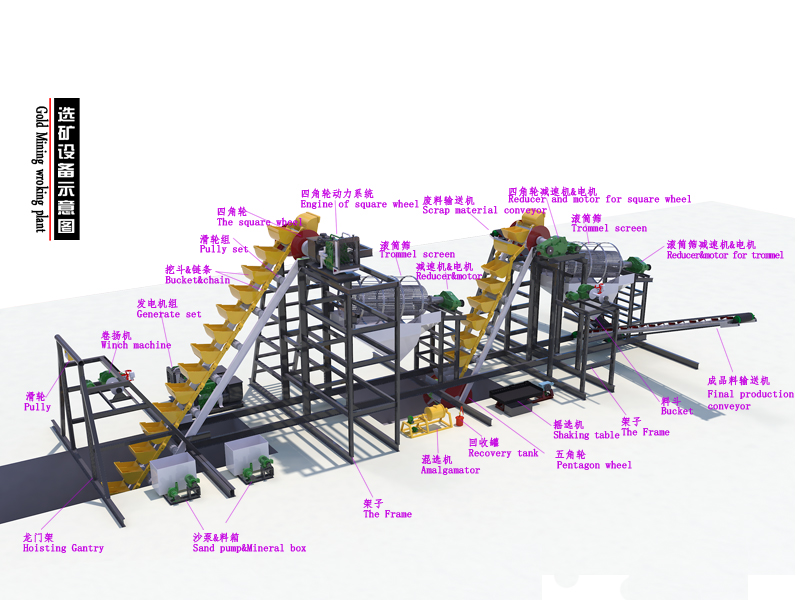

Gold mining machine knelson series centrifuge concentrator is enhanced gravity centrifugal gold equipment based on the principle. In the high times enhanced gravity field, gravity difference proportion and the proportion of small mineral is greatly enlarged, which makes the separation of heavy minerals are more easily than the natural gravity field; and the material bed special design of retaining structure, the flow of water patented technologies and interaction of interference settling down, can continue to maintain a loose state. Under the above conditions, heavy mineral particles can replace the light mineral particles occupy in the sorting bed position and retained, light mineral particles as tailings are discharged, so as to realize the mineral particles by gravity separation.

Gold mining machine knelson series centrifuge concentrator in the production operation, the acceleration of gravity acceleration up to 60 times the enrichment cone or higher, when the pulp into the enrichment cone bottom, effect of slurry under the centrifugal force was thrown to the inner wall of the cone enrichment, and along the inner wall of the upward movement, at the same time by the water inlet hole cone continuous enrichment to make the bed in the cone of injection flow fluidization. In the action of centrifugal force and hydraulic recoil under radial resistance of single gold and other heavy mineral particles can overcome water, centrifugal sedimentation or drilling gap settlement in the bed. While the gangue mineral concentrate because of the less affected by centrifugal force, hydraulic recoil effect hard to overcome the axial force in the axial flow force and centrifugal force Together to promote the discharge of enrichment cone into tailings

Feed size and particle size

knelson series centrifuge concentrator for a wide range of ore size, automatic discharging type is 0 6mm, the recovery of grain is very wide, with the gold recovery as an example, + 38 m for easy recovery of grain, 10 - 38 m for Recyclable grade, - 10 m to difficult recovery grade. In practice, monomer dissociation of gold particles for the majority of Recyclable grade, so this part of single gold is easy to recycle.

Advantages of gold mining machine centrifuge:

A.High concentration of mineral processing, usually can reach 1000-3000 times, the recovery rate is significantly higher than the conventional gravity separation equipment

B.The discharge of concentrate can be realized without shutdown

C. it is a pollution-free, clean and environmentally friendly gold - making equipment without any chemicals

D.knelson series centrifuge concentrator operation rate is high, less power consumption, easy operation and management, the operator must be less, a high degree of automation, equipment daily maintenance is very low, low production costs

Previous content:Guancheng gold refining machine

Next page:Gold seprating dredger types and how to make it more efficient

- Mobile gold car gold mining machine on manufactruing

- Fixed gold mining machine 300 m3/hour alluvial gold mining

- The gold mining equipment mobile concentrator car send to Indonesia

- Affect reason rock gold mine fully crushing&grinding

- The gold mine and separating in Democratic republic of Congo

- Work capacity 100-150ton/hour vibrating gold mining machine

- Stationary type vibrating screen gold mining machine

- Desert gold mining machine dry gold separating plant

- Container Loading:Mobile gold mining machine send

产品分类

/PRODUCTS推荐产品

/PRODUCTS推荐文章

/NEWS- Facts About Environmental Equipment

- To Focus on the Wearing Parts of Roller Crusher

- Some Tips to the Application of the Lubrication of Impact Crusher

- The Development of VSI Crusher Solves the Shortage of the Artificial Sand

联系我们

/CONTACTQingzhou Guancheng Heavy Industrial Machinery Co.,Ltd.

+86 536 3593111

地址:Dongjiande Village, Huanglou Street Office, Qingzhou, Shandong, China (Mainland)

电话:+86 536 3593111

传真:+86 536 3593111

手机:+86 15653473333,15053659999

Email:1592999333@qq.com